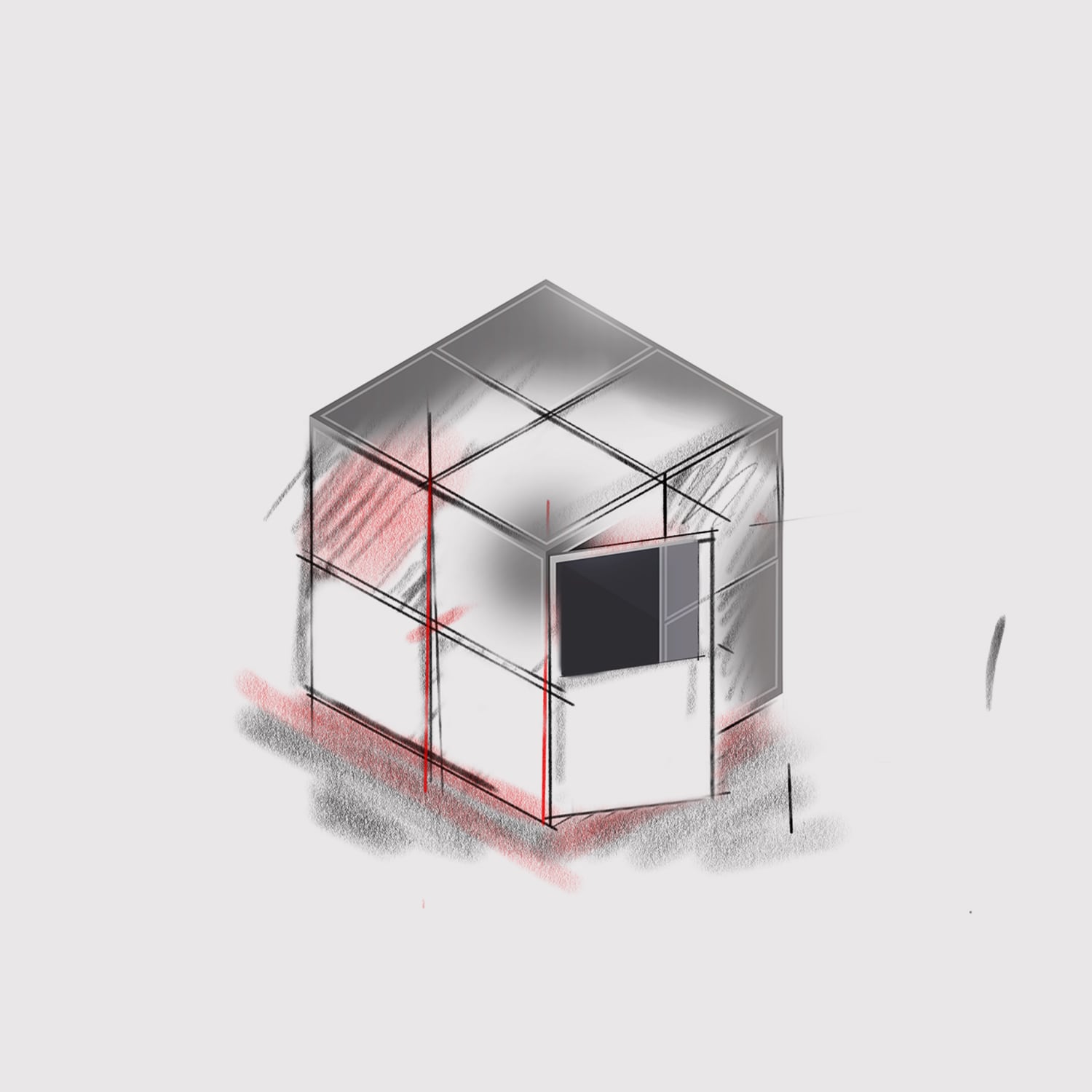

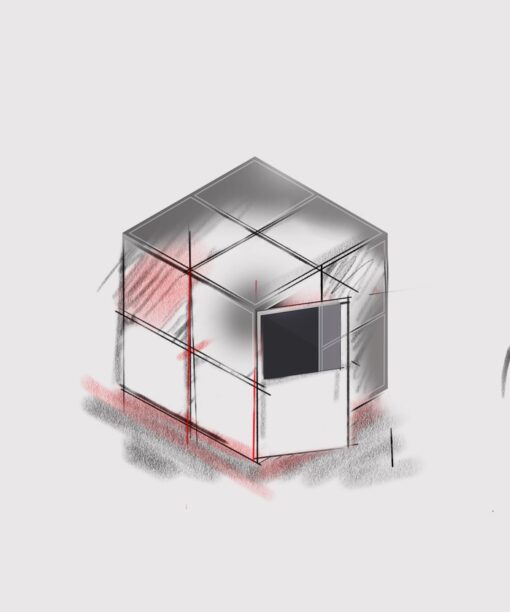

Features of the soundproofed enclosures

The Fonois acoustic enclosures are constructed with a robust, hot-welded galvanised steel load-bearing frame, ensuring excellent structural integrity and long-term durability.

Modular sheet metal panels are internally treated with a multilayer system of sound-insulating, damping, and vibration-absorbing materials to maximise acoustic performance.

The panel surface facing the noise source incorporates a sound-absorbing mat made from non-toxic natural textile fibres, bonded with fire-retardant phenolic resin and protected by a black nonwoven polyester layer (TNT). This configuration leaves 100% of the absorbent surface exposed, ensuring optimal sound absorption and compliance with fire safety and environmental standards.

Thanks to their compact configuration and optimised materials, Fonois soundproofed enclosures offer up to 50% footprint reduction compared to conventional acoustic solutions with equivalent performance. Enclosure components are removable and versatile, featuring high-performance multilayer cladding engineered to deliver excellent sound insulation and absorption. They are suitable for containing noise sources in both indoor production areas and outdoor environments. For applications where partial shielding is sufficient, such as HVAC systems or refrigeration units, Fonois also provides sound barrier solutions, including Quiet Leaf™ noise barriers.

Available models

The following models of soundproofed enclosures are available:

QL Model, developed with innovative Quiet Leaf™ technology, this model combines versatility and low weight, making it ideal for applications requiring consistent and effective acoustic performance.

- On-site noise reduction: up to 25 dB(A)

WL Fire-resistant Model, developed with Wool & Loom™ technology, this version offers high fire resistance rated up to Class A1, making it suitable for ATEX-certified environments. It delivers excellent acoustic performance while meeting stringent safety standards.

- On-site noise reduction: up to 28 dB(A)

- Sound Insulation Index (Rw): 37 dB

BMP Model, engineered with BM Performance™ technology, it is designed for demanding applications where uncompromising acoustic performance and attention to detail are essential.

- On-site noise reduction: up to 40 dB(A)

- Sound Insulation Index (Rw): 49 dB

BMPe Model, developed with innovative BM Performance elite™ technology to achieve maximum performance in any application. Unique in the market, it offers unparalleled soundproofing with a thickness of just 60 mm, combining compact design with exceptional effectiveness.

- On-site noise reduction: up to 47 dB(A)

- Sound Insulation Index (Rw): 54 dB

Technical details

- Dimensions: Modular or tailor-made

- Panel thickness: 50–60 mm

- Operating temperature range: –20°C to +70°C

- Sound absorption coefficient (αw): 0.85 – 0.90

- Fire reaction class: Self-extinguishing (UNI ISO 3795) or Class A1

- Sound insulation index (Rw): 34 – 54 dB

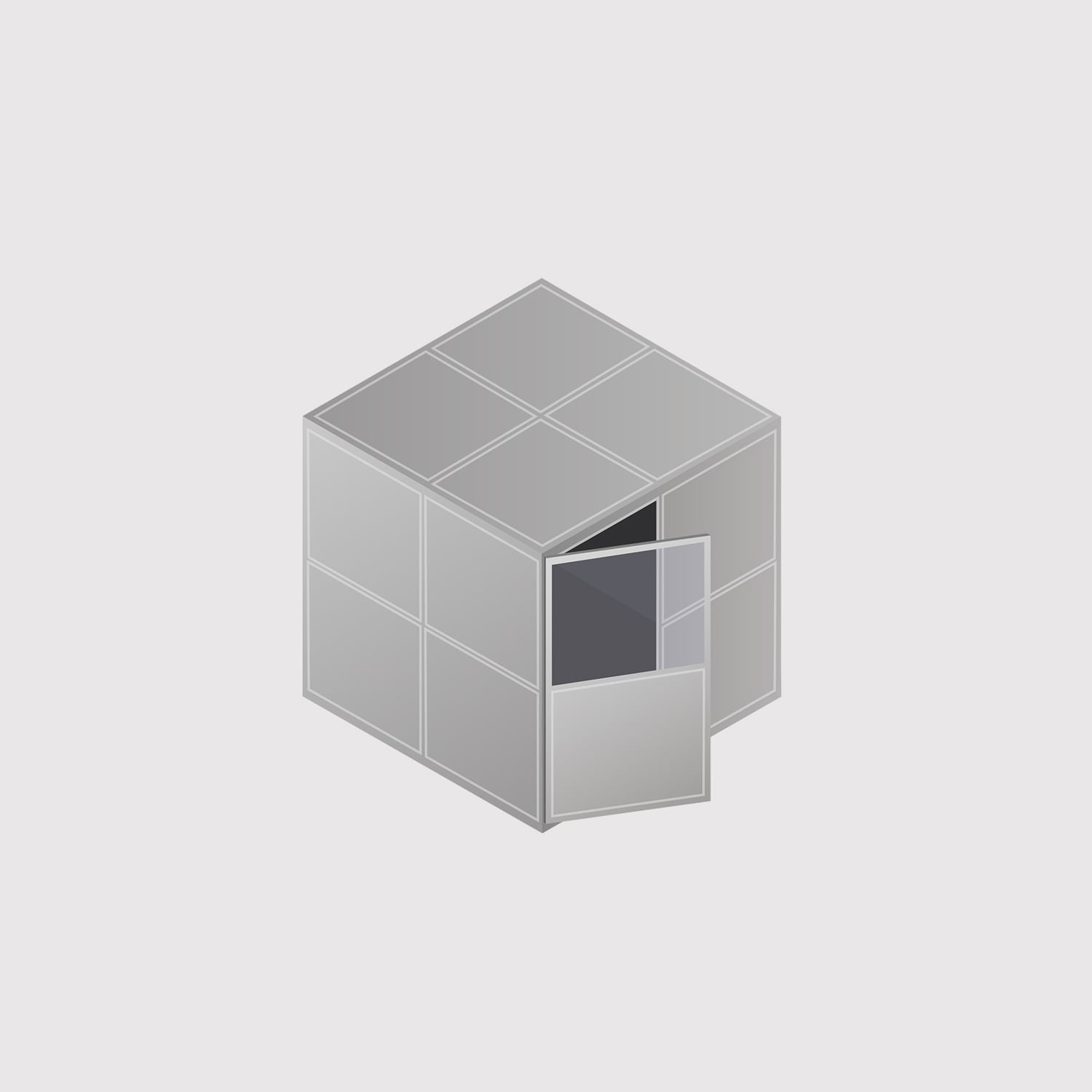

Available integration options

- Provision for integrated silent ventilation systems

- Option to insert glazed sections for visibility or inspection purposes

- Availability of integrated opening components such as hatches, doors, and gates (including sliding doors)

- Integrated automation functionality

- Capability to integrate soundproofed cable and pipe passages

- Possibility of silent tunnels for material transit