Features

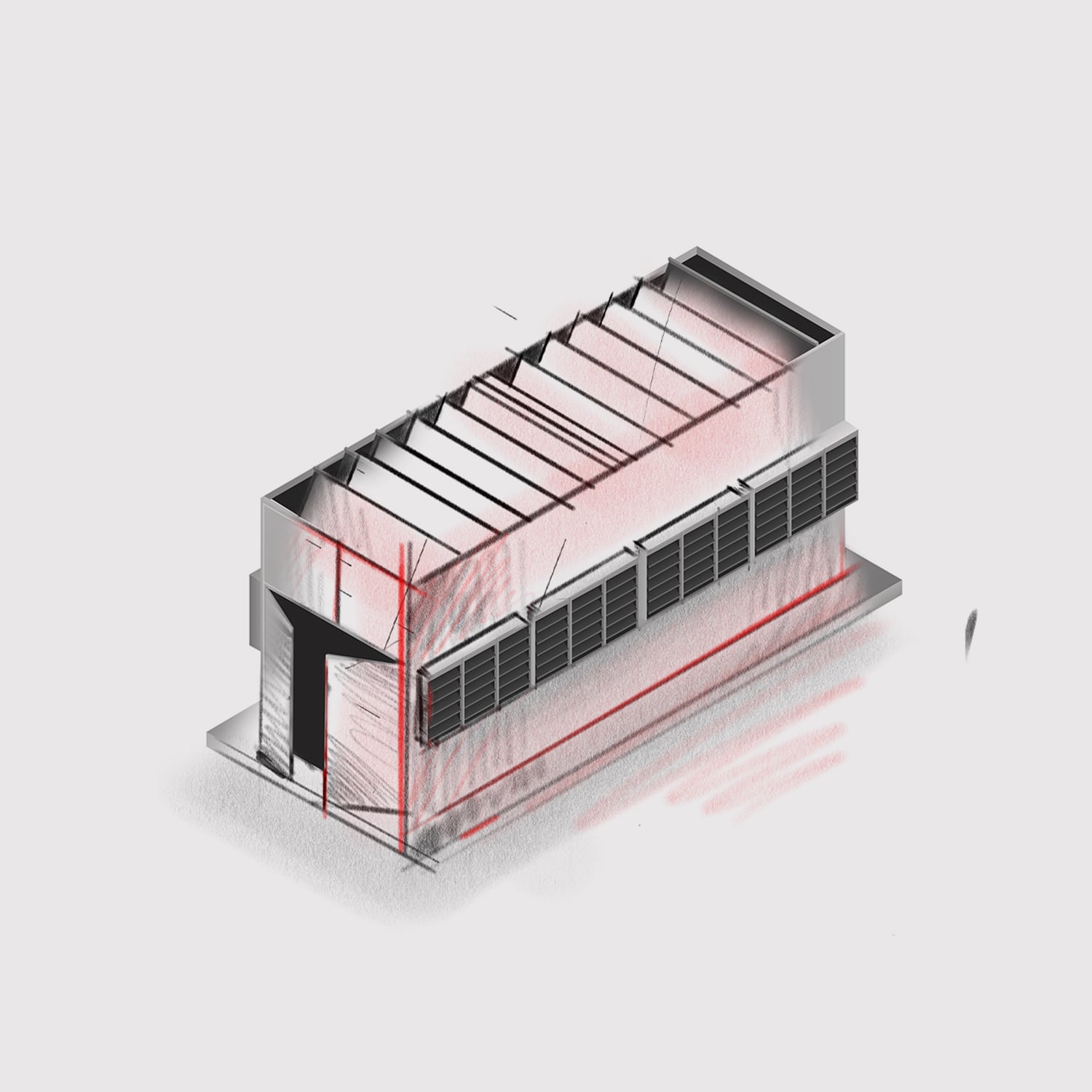

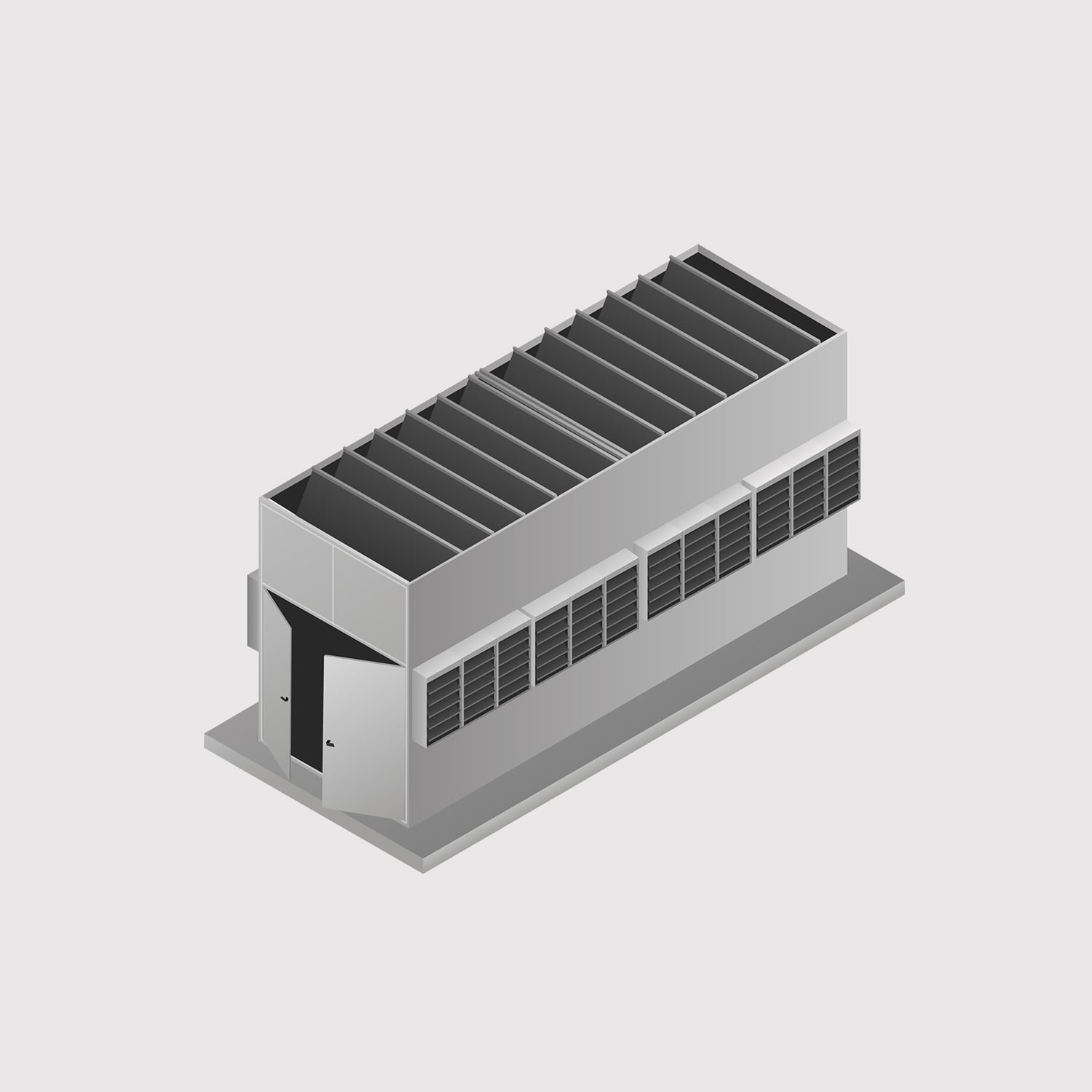

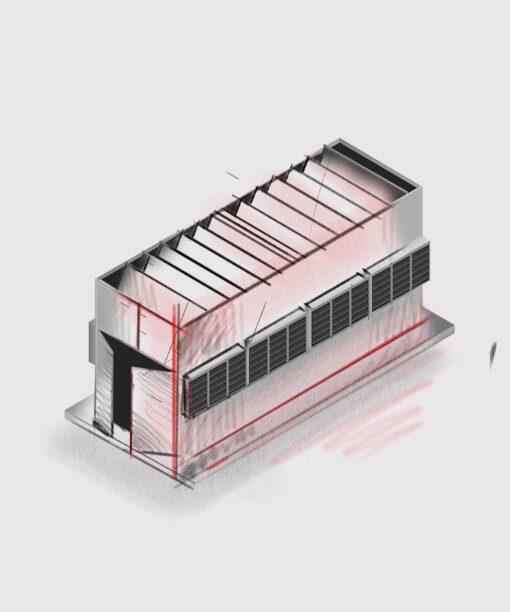

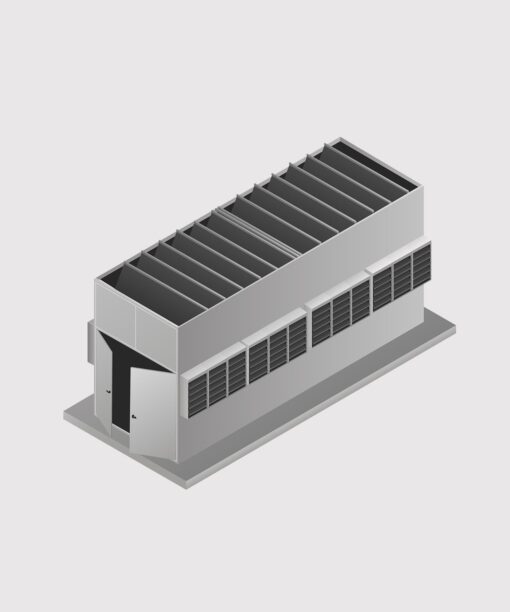

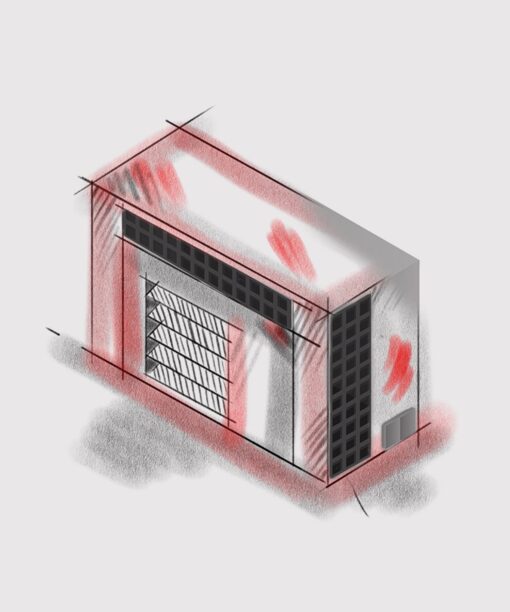

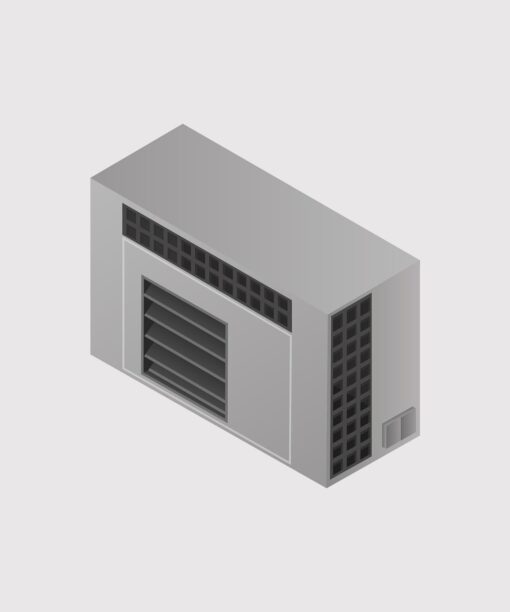

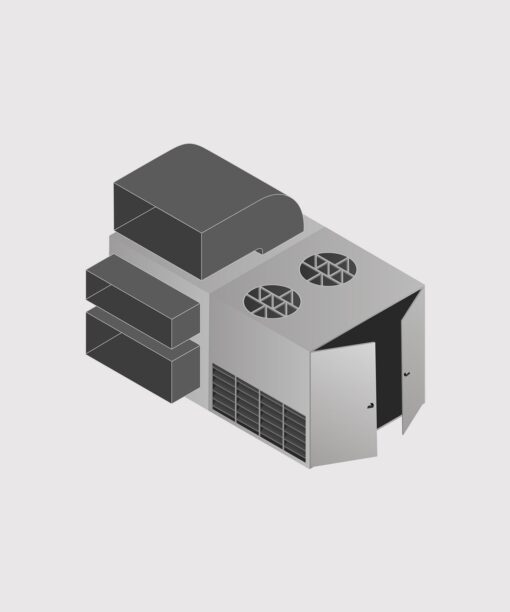

SH Pod Advanced Chiller is a casing designed to acoustically insulate large-size equipment such as chillers, cooling systems, multifunctional units, and refrigeration units. The self-supporting supporting structure makes it completely independent from the machine and is integrated with inspection-accessible panels to allow routine maintenance and ensure easy access to the unit. Thanks to the innovative Slim Hurdle™ technology, which ensures extremely low pressure drops, the casing can be positioned just a few centimetres from the machine, significantly reducing system footprint in technical rooms. The SH Pod is the only product that can be installed within the clearance limits, without altering the unit’s operation.

The casing is fully customisable to any RAL colour, allowing effective aesthetic screening of the units. The top cover and aphonic grilles incorporate 20 mm lamellar baffles, designed to ensure minimal pressure drop, below 10 Pa. Acoustic attenuation is guaranteed up to 19 dB(A).

Technology and Versatility

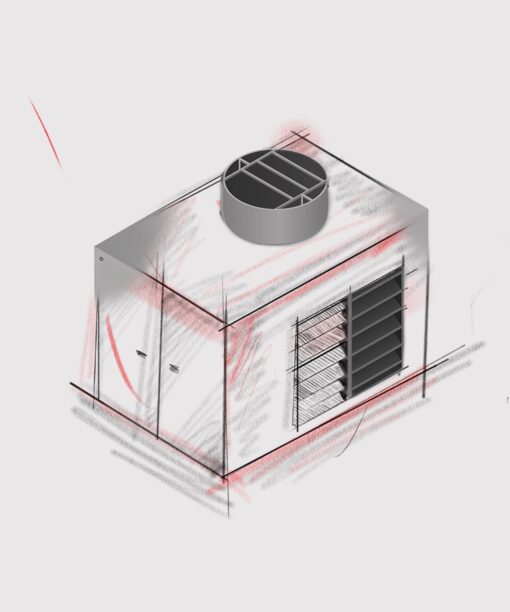

The Advanced Chillers version is designed as a modular solution, allowing seamless adaptation to equipment of any size, whether in V-shaped or vertical configurations.

These units, particularly in multifunctional setups, require high airflow volumes to maintain optimal heat exchanger efficiency and are often equipped with low-pressure fans.

The SH Pod sound-absorbing casing is developed with low pressure drop technology and large open surface areas to support airflow without compromising acoustic performance.

Special attention is given to routine maintenance activities, such as radiator cleaning, performed directly through the spaced sound-absorbing baffles, and access to electrical panels, which is facilitated by simple, functional doors.

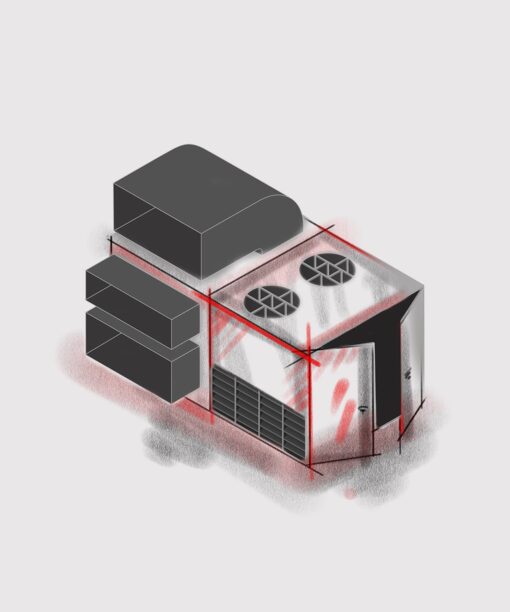

Aesthetics, Protection and Durability of soundproofing casing

Given the substantial size of the equipment enclosed within the SH Pod Advanced Chillers soundproofing casing, there is increasing demand for premium aesthetic screening and bespoke architectural integration. The casing is fully customisable in any RAL colour and can be configured with specialist surface finishes, architectural cladding, or tailored design elements, while maintaining both full functionality of both the casing and the equipment it protects.

As SH Pod casings are often applied to high-value equipment designed for long-term operation, they also play a crucial role in extending the equipment’s lifecycle and lowering maintenance costs. This is achieved through:

- Protection from summer solar radiation, leading to lower energy consumption

- Shielding from environmental elements, reducing long-term degradation

- Protection against extreme events such as hail, minimising maintenance interventions