Features

Thin-baffle silencers leverage innovative Slim Hurdle™ technology and feature sound-absorbing baffles just 20 mm thick. They achieve high acoustic insulation, up to 50 dB(A), through a combination of geometric design and high-performance materials. Offering tailored attenuation from Rw = 10 to 50 dB(A), they maintain up to 90% of the surface area open for airflow, with pressure drops reduced by up to 60% compared to conventional systems. The silencer also includes an insulating and sound-absorbing contour coating to eliminate the breakthrough effect, i.e. lateral sound leakage through the silencer body, typically found in conventional silencers.

The SH™ baffle silencer is used in the following applications:

- On various types of fans, to reduce noise emissions even at low pressure levels

- On air handling units and indoor ventilation systems, to limit noise propagation along ductwork

- On general ventilation systems, to reduce crosstalk between adjacent rooms

- On extraction systems, including high-flow configurations, to minimise noise emitted to the outside

This innovative design delivers excellent sound attenuation while preserving up to 90% high net open surface area for airflow, resulting in significantly reduced pressure drop compared to conventional silencers.

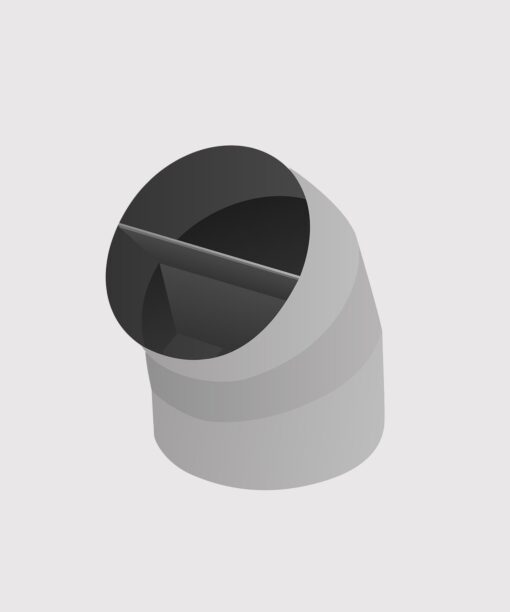

To meet a broader range of design requirements, the silencers are also available in 90° and 45° curved configurations, with both circular and rectangular/square cross-sections—providing maximum flexibility for system integration. For applications requiring noise reduction during air expulsion, Fonois also offers Ring GF Exhaust Acoustic Silencers, developed using the same Slim Hurdle™ technology and optimised for low-pressure fans.

Technical details

- Dimensions: custom-made

- Internal baffle thickness: 20 mm

- Outer coating thickness: 13 mm

- Installation options: flanged or free insertion

- Insertion loss: 10 – 50 dB(A)

Why Slim Hurdle™ acoustic silencers are unique

These acoustic silencers can be easily integrated into any system, including existing installations. Unlike conventional solutions based on rock wool and perforated sheet metal, they offer the following advantages:

- No need to modify the cross-section of ventilation ducts

- No need to oversize systems to maintain functionality

- Enable energy savings through optimised airflow

- Do not require forced straight sections; they can even be manufactured in curved configurations

- Maintain long-term effectiveness, as they are not subject to the breakdown phenomenon typical of conventional silencers